DESIGN PHASE

Every great product starts with an idea. We start by recognising a product that can be improved, and we research if there's a need for it in the market.

Research includes looking at what's already out there, asking riders what they'd like to see in a new product, and testing out existing products ourselves.

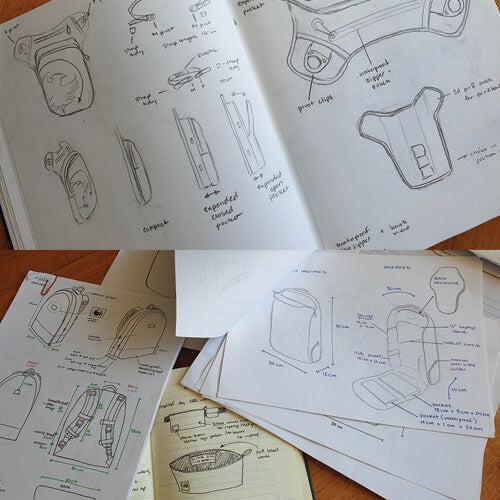

Designing a product involves getting a heap of ideas on paper and prioritising the most wanted and most practical features. Then we sketch out a few ways we think these features can be achieved, in the most aesthetically pleasing and user-friendly way.

After sketching a few ideas, we create prototypes in-house using a range of materials. This includes cardboard, fabrics, foam, staples, and even duct tape.

The idea is to create the general shell of the product so that we can visibly see how it'll look and feel in person. This helps us avoid bringing avoidable mistakes into the sample phase.

Finally, we take photos of the prototype and sketches, create digital blueprints for them, and send them to our manufacturer.

SHOP MOTORCYCLE GEAR

We run both Flying Solo Gear Co and our sister company Peak Moto out of the same location

You can check out our entire FSGC range of bags and luggage in-store.

Peak Moto is a retailer of women's motorcycle gear including MotoGirl, Alpinestars, REV'IT, 4SR, Ricondi, and more!

We stock motorcycle jackets, pants, boots, and gloves. Be sure to check it out!